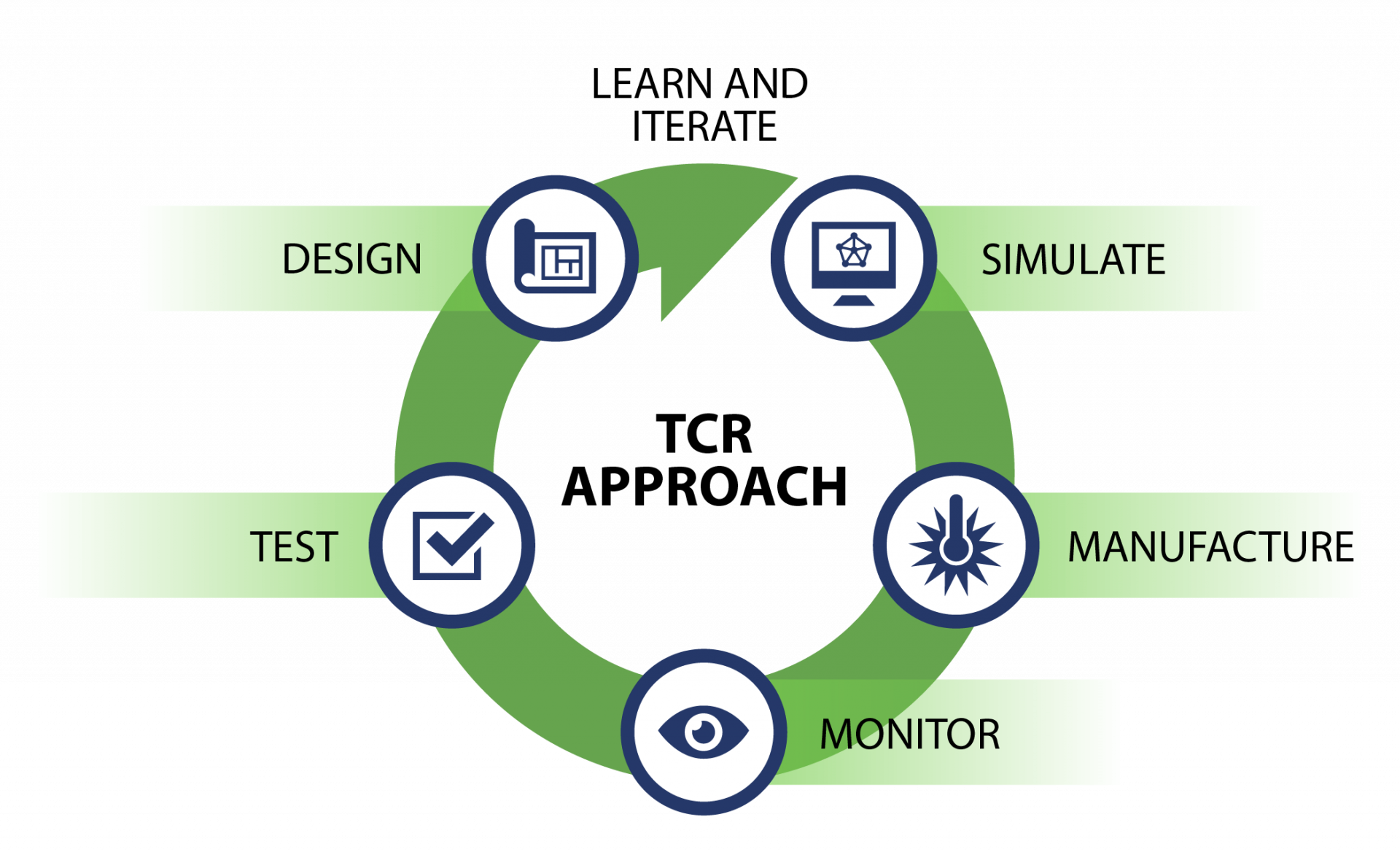

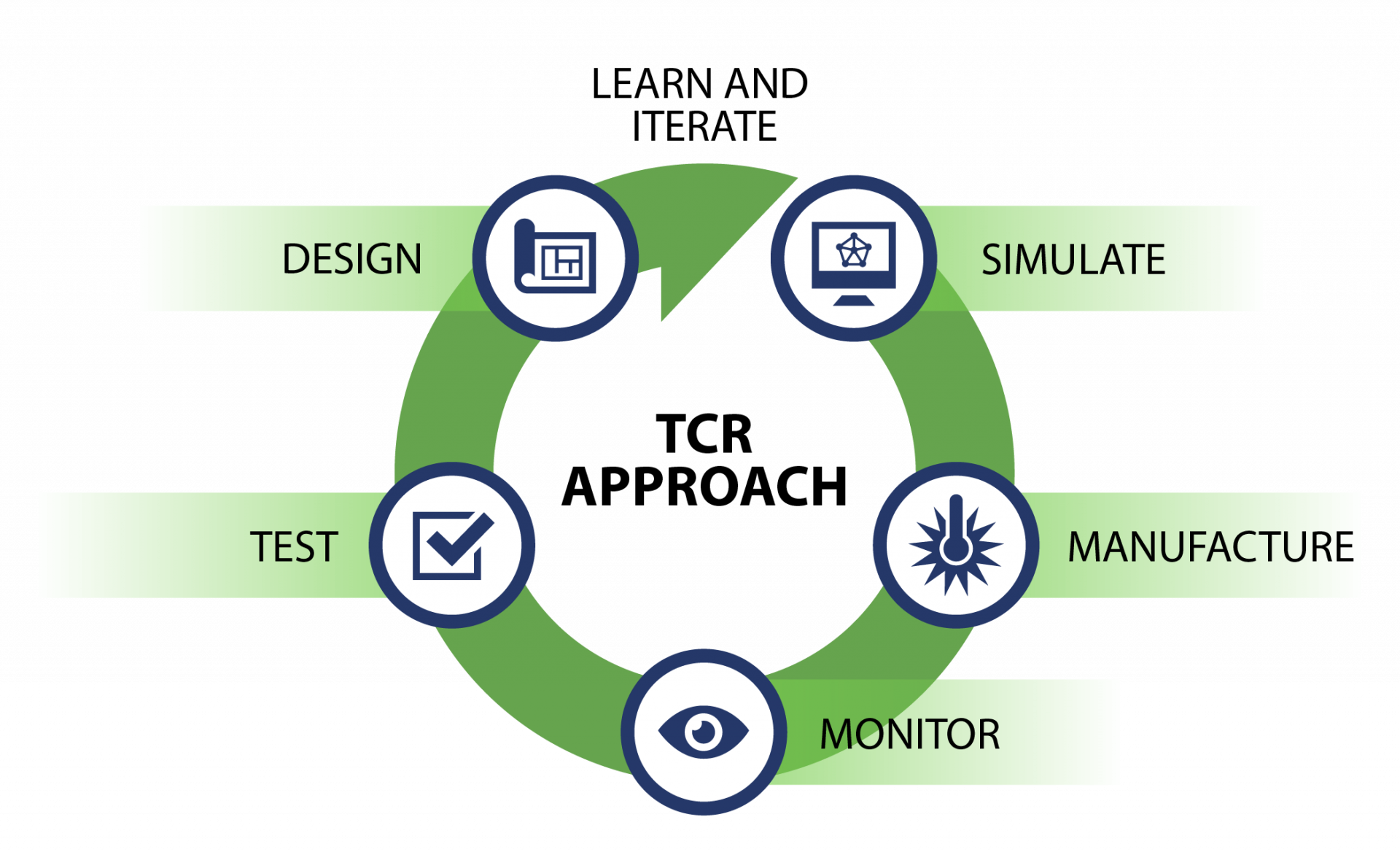

The DOE’s Transformational Challenge Reactor program is harnessing recent advances in manufacturing, materials, and computational sciences to rapidly build and operate an advanced reactor core.

The TCR program is leveraging an agile approach—one that is centered around continuously informing the process—to accelerate deployment timelines and introduce performance improvements. Image: Adam Malin, ORNL

Soon after Enrico Fermi’s Chicago Pile-1 went critical for a brief duration in December 1942, the construction of the first continuously operating reactor, the X-10 Graphite Reactor, was initiated in February 1943 at Clinton Engineer Works in Oak Ridge, Tenn. On November 4 of that year, a mere nine months after the start of construction, the reactor began operation. This marked the onset of what Alvin M. Weinberg referred to as “the first nuclear era,” during which many reactors of various designs and operating parameters were built and demonstrated across the United States. Forty years ago, the Fast Flux Test Facility was the last U.S. non-light-water reactor to reach criticality, and it has since been decommissioned.

The interior of the process building at the American Centrifuge Plant in Piketon, Ohio, where Centrus Energy plans to operate a HALEU demonstration cascade by June 2022. (Photo: Centrus Energy)

Advanced reactor cores are being designed for higher efficiencies and longer lifetimes, but to get there, they need high-assay low-enriched uranium (HALEU).

Enriched to between 5 and 19.75 percent fissile U-235, HALEU is packed with nuclear potential. It can be used as a feedstock for the demonstration of new fuel designs, from uranium alloys to ceramic pellets and liquid fuels. Those fuels can enable advanced reactor and microreactor demonstrations. Operating light-water reactors could potentially transition to HALEU uranium oxide fuels for extended operating cycles and improved plant economics.